The ACTT Tilt Cable Kit 66B5000K003 is a crucial part in the world of tilt systems, particularly in industrial and vehicle maintenance environments where reliability and mechanical precision are non-negotiable. While the part number may seem technical at first glance, its application and relevance are quite broad. If you’ve come across this term during a repair, procurement, or parts replacement project, understanding the ACTT tilt cable kit 66B5000K003 is essential to ensuring operational continuity and safety.

In this article, we’ll explore all major aspects of the ACTT tilt cable kit 66B5000K003 including its purpose, construction, compatibility, installation notes, and common usage scenarios. This guide is crafted to help both technical and non-technical readers grasp the importance of this kit in the mechanical chain of tilt-operated equipment.

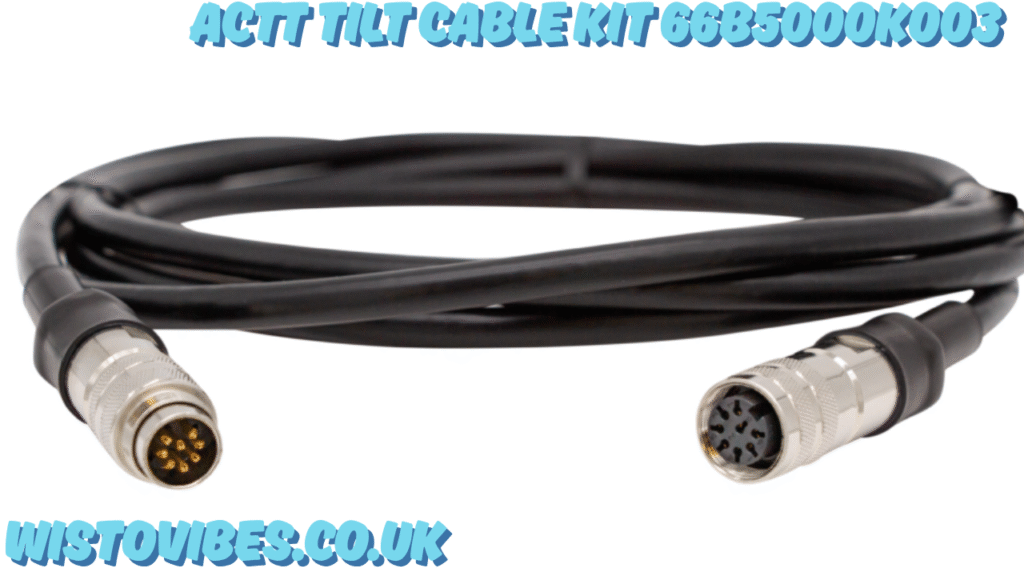

What Is the ACTT Tilt Cable Kit 66B5000K003??

The ACTT tilt cable kit 66B5000K003 is a specialized assembly designed for controlling tilt functions in mechanical or hydraulic systems. This can include tilt steering columns in vehicles, forklift tilt mechanisms, or other automated tilt-control equipment where cable-driven systems are employed.

The part number “66B5000K003” specifically denotes a product variation in ACTT’s lineup, which can refer to particular measurements, end fittings, or material specifications. While the complete configuration can vary depending on the manufacturer’s data sheet, this kit typically includes:

- Heavy-duty tilt cable

- Mounting hardware (brackets, clips)

- Cable sheath or conduit

- Connector fittings

- Installation guide or schematic (depending on supplier)

Understanding the Function of a Tilt Cable Kit

In any tilt system, cables are used to convert motion from one point to another. The ACTT tilt cable kit 66B5000K003 helps transfer motion or torque from a control point—such as a lever or hydraulic actuator—to the part of the system that physically performs the tilting action.

This could be:

- Tilting the steering column in a utility vehicle.

- Adjusting the angle of a forklift mast.

- Altering the tilt angle in a platform or seat in heavy machinery.

The precision with which this cable operates is vital. A failure in the cable can lead to immobilized machinery, inaccurate movement, or even pose safety hazards during operation.

Applications of the ACTT Tilt Cable Kit 66B5000K003

While ACTT may not be as universally recognized as brands like Morse or Teleflex, many specialized equipment manufacturers use ACTT components for their high-quality build and customization. Common application fields include:

- Industrial forklifts

- Material handling equipment

- Agricultural machinery

- Aerial work platforms

- Heavy-duty construction vehicles

Because tilt mechanisms are a basic ergonomic and functional feature in these systems, a faulty or missing cable kit like the 66B5000K003 can significantly affect usability.

Key Features of the ACTT Tilt Cable Kit 66B5000K003

When it comes to parts replacement or selection, understanding what sets the ACTT tilt cable kit 66B5000K003 apart is key. Here are the core features that users should expect:

1. Durable Cable Construction

Built to resist wear, rust, and environmental damage. Often constructed with braided steel or high-tensile synthetic cores.

2. Smooth Motion Control

Low-friction inner lining to ensure precise motion transmission with minimal resistance.

3. Flexible Sheathing

The outer sheath is often built from flexible but durable rubber or polymer to navigate tight spaces without cracking.

4. Pre-Fitted Ends

Cable ends are typically pre-attached with eyelets, ball joints, or pin connectors suited for tilt mechanisms.

5. Universal or Specific Fit

While some versions are made universal, the 66B5000K003 version is likely tailored for a specific tilt configuration or model, making it important to match your exact part requirement.

Installation Considerations for ACTT Tilt Cable Kit 66B5000K003

Installing the ACTT tilt cable kit 66B5000K003 can be straightforward if done with care. However, improper installation can lead to cable failure or compromised motion control. Here are general guidelines:

a) Preparation

- Disconnect power to the equipment.

- Identify the tilt control mechanism.

- Locate all access points and existing cable routes.

b) Cable Routing

- Avoid sharp bends or kinks.

- Use supplied mounting brackets to secure the cable sheath.

- Ensure no interference with other moving parts.

c) End Connection

- Attach the cable ends to their respective actuator or tilt arm connectors.

- Tighten all fasteners securely to manufacturer-recommended torque values.

d) Testing

- Move the tilt control slowly to ensure smooth motion.

- Check for any resistance or snapping movement.

- Adjust if necessary before full operation.

Signs You May Need a Replacement Cable Kit

Recognizing the signs of a failing or damaged tilt cable can prevent costly downtime. Some common symptoms include:

- Stiff or unresponsive tilt controls

- Inconsistent or jerky tilt movement

- Visible fraying or corrosion on the cable

- Unusual noises during tilt operation

- Complete loss of tilt functionality

If any of these signs are present, checking the ACTT tilt cable kit 66B5000K003 and replacing it if needed can restore full system performance.

Maintenance Tips for Extending Cable Kit Life

Even high-quality cable kits like the ACTT 66B5000K003 benefit from regular maintenance. Here are a few tips:

- Inspect quarterly: Visually inspect for wear, kinks, and rust.

- Lubricate when necessary: Use only manufacturer-approved lubricants.

- Avoid moisture accumulation: If used in outdoor or humid environments, use protective wraps or enclosures.

- Do not overload: Always operate within tilt system’s rated load and angle specifications.

Comparing ACTT Tilt Cable Kit 66B5000K003 to Similar Kits

Other cable kits in the market may resemble the ACTT tilt cable kit 66B5000K003, but not all are created equal. Cheaper alternatives may lack the tensile strength or precise engineering needed for reliable performance.

Some kits worth comparing include:

- Morse 33C and 43C series cables

- Teleflex tilt control cables

- OEM-specific tilt kits for Toyota or Hyster forklifts

However, ACTT’s part number 66B5000K003 remains a go-to for systems originally built with that configuration, making it a trusted replacement part.

FAQs About ACTT Tilt Cable Kit 66B5000K003

Q1: Is ACTT tilt cable kit 66B5000K003 compatible with all tilt systems?

A: No. It is typically built for specific models or equipment. Always cross-check part numbers with the equipment manual.

Q2: Can I install the tilt cable kit myself?

A: Yes, if you are mechanically inclined and have access to proper tools. However, professional installation is recommended for safety.

Q3: How long does this cable kit last?

A: When properly installed and maintained, it can last several years under regular use.

Q4: Can this kit be modified?

A: It’s not advisable to modify factory-manufactured kits like the ACTT tilt cable kit 66B5000K003, as this may compromise function and void warranties.

Q5: What if my system doesn’t move after installing the kit?

A: Double-check the routing, connections, and any actuator locks. Also ensure there are no bends or binding points in the cable.

Final Thoughts on the ACTT Tilt Cable Kit 66B5000K003

The ACTT tilt cable kit 66B5000K003 plays a small but critical role in tilt control systems across various industrial, agricultural, and utility applications. Its durability, precision, and compatibility with specific tilt systems make it a valuable part that should not be overlooked.

Whether you are performing a routine replacement or addressing a malfunction, ensuring you have the correct kit—and that it’s installed properly—will enhance safety, usability, and longevity of your tilt-equipped machinery. Always refer to equipment documentation or consult a technician when in doubt.

Also read : Sodziu: Understanding Its Cultural and Linguistic Significance