Retrofitting safety systems is essential for older machinery in industrial environments, especially for equipment like shearing machines. The light curtain for retrofit baccur shear, ??, has emerged as a crucial solution for those aiming to upgrade existing shearing systems for improved operator safety, productivity, and compliance with evolving safety regulations.

This comprehensive guide explores what a light curtain for retrofit baccur shear, ??, entails, how it functions, and why integrating it is a forward-thinking move for manufacturers and metal fabricators.

Understanding the Need for Light Curtain for Retrofit Baccur Shear, ??

Baccur shears, known for their robust cutting and shearing capabilities in heavy industrial environments, often predate the integration of modern safety mechanisms. Operators work in proximity to moving blades and mechanical parts, which poses significant safety hazards.

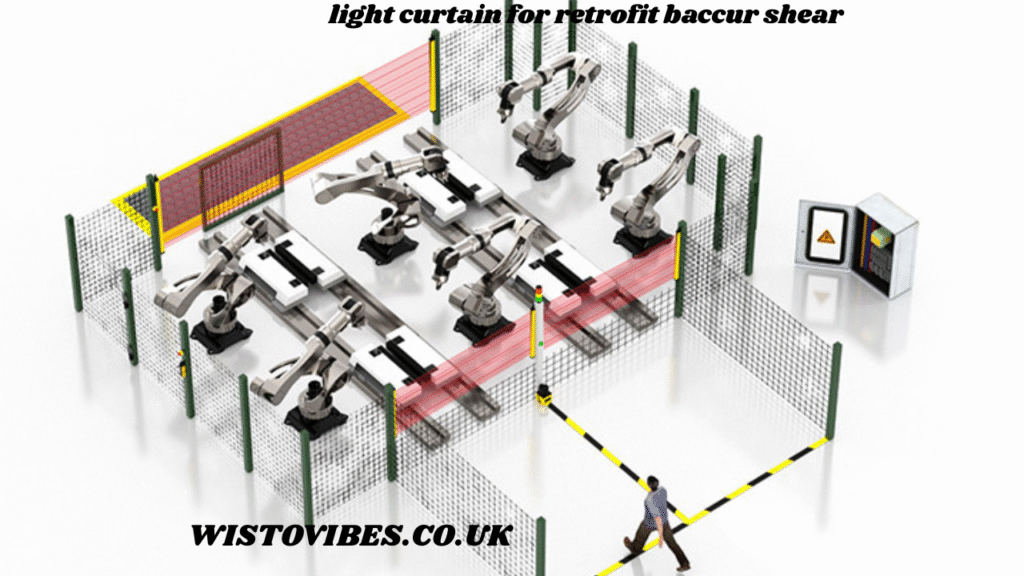

The light curtain for retrofit baccur shear, ??, provides a non-intrusive, highly reliable safety solution that instantly stops the machine when an obstruction, such as a hand or object, enters the hazardous zone. Retrofitting older baccur shears with this advanced safety system ensures worker safety while minimizing operational downtime.

What is a Light Curtain for Retrofit Baccur Shear, ??

A light curtain for retrofit baccur shear, ??, is an array of infrared light beams emitted between two units (transmitter and receiver) mounted on either side of the shearing area. When any object interrupts these beams, the system sends a signal to halt the shear’s operation immediately, preventing injury and mechanical damage.

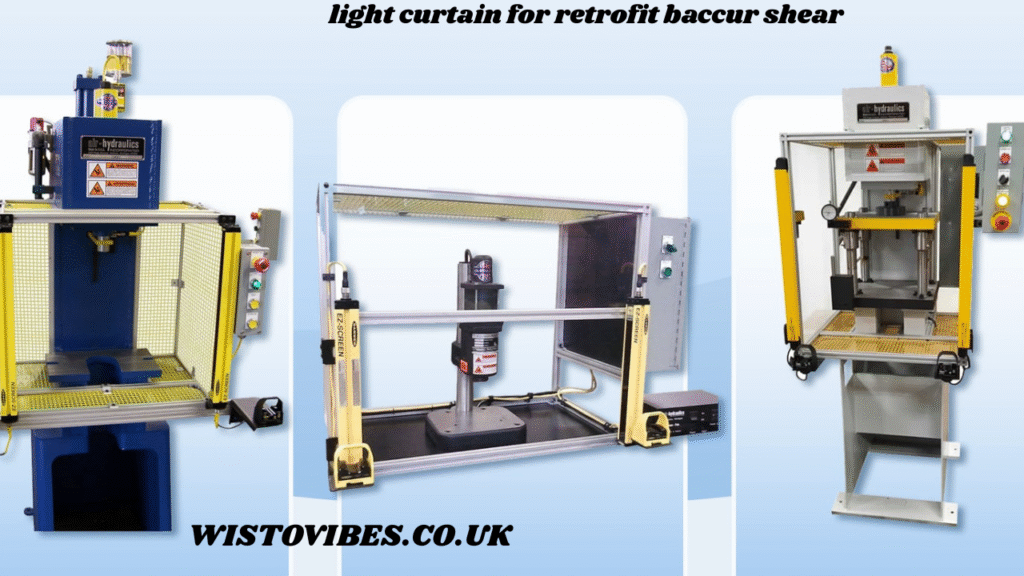

The system is designed specifically for retrofit applications, allowing seamless integration with existing baccur shear control systems without extensive modifications, making it a cost-effective safety upgrade.

Key Benefits of Light Curtain for Retrofit Baccur Shear, ??

1. Enhanced Operator Safety

The primary advantage of using a light curtain for retrofit baccur shear, ??, is improved worker safety. The immediate stop function upon beam interruption ensures the operator’s hands or limbs are protected from the cutting edge.

2. Compliance with Safety Standards

Many regions require compliance with updated machinery safety standards. Installing a light curtain for retrofit baccur shear, ??, helps organizations meet these regulations, reducing legal liabilities and maintaining operational certification.

3. Increased Productivity

Contrary to fears that safety systems slow down work, the light curtain for retrofit baccur shear, ??, enables efficient workflow by reducing the need for mechanical guards that require manual removal and reattachment. Operators can maintain focus while working within a safer environment.

4. Cost-Effective Retrofit

Investing in new machinery with integrated safety systems can be costly. A light curtain for retrofit baccur shear, ??, allows businesses to upgrade existing shearing machines without the capital expenditure associated with new equipment.

Technical Considerations When Installing Light Curtain for Retrofit Baccur Shear, ??

Beam Resolution and Detection Capability

A light curtain for retrofit baccur shear, ??, should have sufficient resolution to detect objects of small diameter, ensuring even a finger-sized intrusion is detected. This ensures the highest level of safety.

Response Time

Fast response time is critical in the shearing process. The light curtain for retrofit baccur shear, ??, should be capable of sending stop signals to the shear within milliseconds, minimizing the stopping distance to prevent injuries.

Integration with Existing Controls

Retrofitting requires that the light curtain for retrofit baccur shear, ??, integrates seamlessly with the shear’s current electrical and control systems, including emergency stop circuits and operational relays.

Environmental Suitability

Industrial environments often involve dust, oil, and vibrations. A light curtain for retrofit baccur shear, ??, should be robust enough to operate reliably in such conditions, including self-monitoring for misalignment or obstruction.

Installation Process of Light Curtain for Retrofit Baccur Shear, ??

- Site Assessment: Engineers assess the existing baccur shear setup, identifying mounting points and wiring configurations for the light curtain system.

- Designing Mounting Structures: Brackets and frames are designed to position the light curtain for retrofit baccur shear, ??, at the correct height and position relative to the cutting zone.

- Electrical Integration: The light curtain’s control unit is wired to the shear’s emergency stop circuitry and tested for reliable interruption of power during beam blockage.

- Calibration and Testing: The system undergoes rigorous testing, including intentional interruptions to confirm proper stopping distances and response times.

- Operator Training: Staff are trained on the functionality and importance of the light curtain for retrofit baccur shear, ??, ensuring adherence to safety protocols.

Challenges Faced When Using Light Curtain for Retrofit Baccur Shear, ??

While a light curtain for retrofit baccur shear, ??, significantly enhances safety, challenges include:

- False Triggers: Unintentional objects or reflective surfaces may cause unnecessary interruptions if the system is not calibrated properly.

- Maintenance Needs: Regular cleaning and alignment checks are necessary to maintain consistent functionality.

- Space Limitations: Retrofitting may be challenging in tight spaces if there is limited clearance around the shear for mounting the light curtain components.

Cost Implications of Light Curtain for Retrofit Baccur Shear, ??

The investment in a light curtain for retrofit baccur shear, ??, varies based on:

- The size and resolution of the light curtain.

- The complexity of electrical integration with the existing shear.

- The customization required for mounting and environmental considerations.

However, the long-term benefits of injury prevention, reduced downtime due to accidents, and regulatory compliance typically outweigh initial costs.

Future of Safety with Light Curtain for Retrofit Baccur Shear, ??

As manufacturing environments embrace Industry 4.0, safety systems like the light curtain for retrofit baccur shear, ??, will continue to evolve, integrating:

- IoT Monitoring: Allowing predictive maintenance alerts when beam alignment issues or dirt accumulation are detected.

- Smart Diagnostics: Providing live feedback to operators about system health and obstruction status.

- Data Analytics: Helping companies analyze safety event patterns to improve operational layouts and reduce risks further.

Conclusion: Why a Light Curtain for Retrofit Baccur Shear, ??, is a Strategic Safety Investment

Retrofitting older baccur shear systems with a light curtain for retrofit baccur shear, ??, is a strategic decision that addresses safety, productivity, and compliance challenges in modern manufacturing.

By providing a non-intrusive, highly effective safety barrier, this system protects operators while allowing efficient shearing operations, extending the service life of existing equipment without compromising safety.

For manufacturers looking to enhance workplace safety while managing costs, investing in a light curtain for retrofit baccur shear, ??, is a practical and forward-thinking step in aligning with modern safety and operational excellence practices.

Also Read : Does the Name Monkeyfist Have Norwegian Meaning, ?