Introduction to the Polini Thor 250 CDI Pickup: A Technical Marvel in Paramotor Engineering

The phrase “polini thor 250 cdi pickup” may sound highly specific, but within the circles of paramotor pilots, aviation engineers, and performance tuning experts, it holds substantial weight. The Polini Thor 250 is already known as one of the most powerful and refined engines in the paramotor and ultralight category. Its CDI pickup system, a crucial part of its ignition and timing mechanism, significantly enhances the precision, efficiency, and responsiveness of the engine.

This article explores all aspects of the polini thor 250 cdi pickup, from how it functions, to how it contributes to the engine’s performance, and what makes it critical for serious users of the Polini Thor 250 engine platform. We’ll also address its implications on tuning, maintenance, and performance output.

Understanding the Basics: What Is the Polini Thor 250 Engine?

Before diving into the specifics of the CDI pickup, it’s essential to understand the Polini Thor 250 itself. Developed by Polini Motori, a renowned Italian manufacturer, the Thor 250 is a 2-stroke, liquid-cooled, single-cylinder engine designed specifically for paramotors, trikes, and other lightweight aviation or high-performance applications.

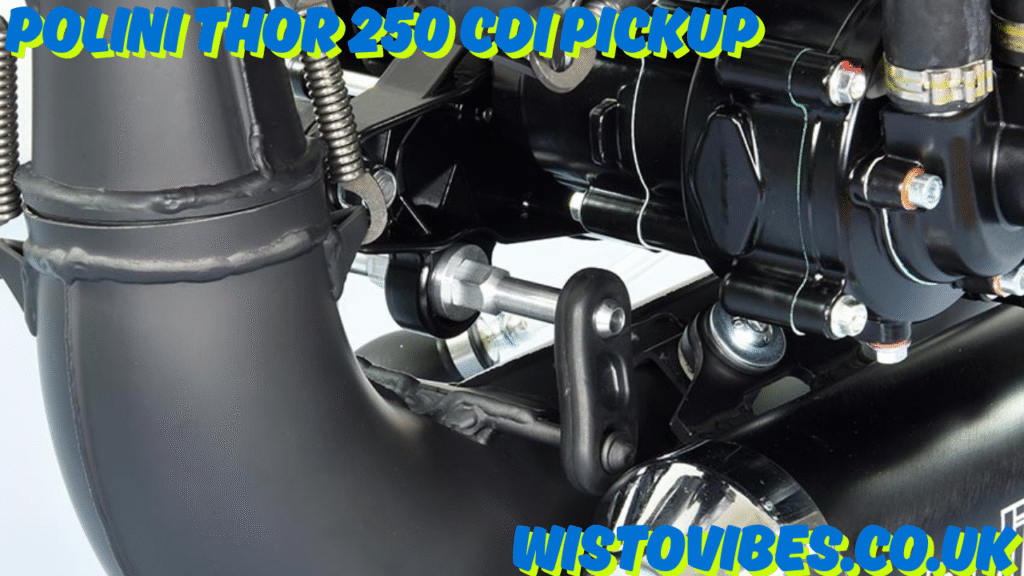

The Thor 250 stands out for its high power-to-weight ratio, reliability, and advanced features like electronic fuel injection (EFI), counter-rotating shaft, centrifugal clutch, and dual spark plugs for better combustion stability. But what truly supports its fine-tuned performance is the ignition system — more specifically, the CDI and pickup module.

What Is a CDI Pickup and Why Does It Matter?

CDI stands for Capacitor Discharge Ignition. In simple terms, a CDI pickup is a sensor that triggers the CDI box to release a spark at the exact right time during the engine’s operation. In the polini thor 250 cdi pickup setup, this timing sensor plays a critical role in optimizing ignition timing based on engine RPM and crankshaft position.

The pickup is typically installed near the flywheel or magneto and generates a small voltage pulse every time a magnet on the flywheel passes. This pulse is interpreted by the CDI, which then releases a high-voltage jolt to the ignition coil, sparking the engine. The timing of this spark is what ensures smooth operation, power output, and fuel efficiency.

CDI Pickup in the Polini Thor 250: Precision Meets Performance

In the polini thor 250 cdi pickup system, the engineering is focused on achieving precise timing without reliance on moving parts susceptible to wear. The CDI unit, combined with a high-sensitivity pickup coil, ensures that the ignition occurs at the optimal point in the combustion cycle.

Key features of the Thor 250’s CDI pickup system include:

- Digital timing curve: Engine RPM data helps adjust timing dynamically.

- Redundancy with dual spark plugs: Even if one ignition fails, the second provides a backup spark.

- Enhanced cold start performance: Proper pickup functioning leads to faster and cleaner engine starts.

- Better throttle response: Real-time ignition adjustment makes throttle behavior sharper and more predictable.

This system is particularly vital in aviation, where engine reliability is not a convenience but a safety necessity.

How Does the Polini Thor 250 CDI Pickup Compare to Other Models?

When compared with other Polini engines like the Thor 200 or competing models like Vittorazi Moster 185, the polini thor 250 cdi pickup system offers more robust spark management. The pickup sensor in the 250 operates at a higher precision level and pairs with a more complex CDI unit.

Whereas many simpler 2-stroke engines rely on fixed ignition points or analog CDI boxes, the Thor 250 uses an advanced digital ignition system, making it superior in combustion control, especially at variable altitudes and RPMs — a critical aspect for paramotorists and ultralight pilots who often encounter different air densities and environmental conditions.

Common Issues and Maintenance Tips for the CDI Pickup

Even though the polini thor 250 cdi pickup is engineered for durability, like any electronic component exposed to vibrations, heat, and weather, it can face wear and failure over time.

Common issues include:

- Intermittent starting problems: This could point to a failing pickup sensor or misaligned flywheel.

- Engine misfires at high RPMs: Could indicate the CDI not receiving proper timing pulses.

- Erratic RPM or stalling: Usually caused by weak signal from the pickup due to debris or magnetic interference.

Maintenance Tips:

- Inspect the pickup sensor every 50 flight hours.

- Clean the flywheel area and ensure no metallic debris or corrosion is present.

- Use a multimeter to test pickup resistance (usually specified in the engine manual).

- Always check grounding wires and cable connections for corrosion.

Upgrading or Replacing the CDI Pickup in Polini Thor 250

Users of the polini thor 250 cdi pickup system often consider upgrades, especially for tuning or high-altitude usage. Aftermarket high-performance CDI boxes exist, which can provide alternative ignition curves and better spark energy. However, compatibility with the original pickup sensor is essential.

When replacing the pickup:

- Make sure you use the original Polini-specified sensor.

- Align the sensor precisely with the flywheel magnet timing mark.

- Use torque specifications when fastening — over-tightening can crack the sensor mount.

Why the Polini Thor 250 CDI Pickup Is a Tuner’s Dream

Tuning enthusiasts often find the polini thor 250 cdi pickup setup ideal for experiments in ignition mapping and performance enhancement. With proper tools and programmable CDI units, it’s possible to remap the ignition curve for specific conditions, such as high-humidity environments, high-altitude flying, or even fuel-grade compensation.

Also, the responsiveness of the CDI system allows for smoother transitions when integrating electronic fuel injection or throttle-position-sensor-based ignition advance.

Implications for Pilots and DIY Builders

For paramotor pilots, the functionality of the polini thor 250 cdi pickup goes beyond technical specs — it directly affects safety and confidence during flight. A malfunctioning pickup can cause power drops mid-air, delayed response during takeoff, or unreliable performance during climbing.

DIY builders and frame assemblers benefit from understanding the positioning, shielding, and wiring of the pickup to avoid electromagnetic interference (EMI) from nearby components like starter motors or battery regulators.

CDI Pickup Troubleshooting Checklist for the Thor 250

- Engine fails to start – Check pickup wiring, test for pulse output.

- Backfiring or popping – Likely incorrect ignition timing or faulty pickup.

- Engine bogs under load – Test coil and CDI in conjunction with pickup signal.

- Overheating – Improper spark timing could lead to advanced combustion.

Knowing these behaviors can save time during field repairs or in pre-flight checks.

Conclusion: Polini Thor 250 CDI Pickup?? A Cornerstone of Precision Ignition

The polini thor 250 cdi pickup isn’t just a technical footnote in the engine’s manual — it’s a central component in the engine’s overall intelligence. For an engine like the Thor 250, known for its high output and reliability, the CDI pickup ensures the spark is always timed right, every time, across all conditions.

Whether you’re a pilot flying over alpine terrains or a mechanic tuning engines in your workshop, the reliability and sophistication of the polini thor 250 cdi pickup make it a vital piece of performance technology. When paired with good maintenance habits and proper understanding, it offers unparalleled ignition accuracy, helping the Polini Thor 250 engine live up to its powerful reputation.

FAQs about Polini Thor 250 CDI Pickup

Q1: What does the CDI pickup do in the Polini Thor 250?

A: It senses crankshaft position and triggers the ignition at the precise timing point for combustion.

Q2: How often should I inspect the CDI pickup?

A: Ideally every 50 flight hours or during routine engine inspections.

Q3: Can I replace the CDI pickup myself?

A: Yes, if you follow correct alignment, torque settings, and safety practices.

Q4: What are signs of a faulty CDI pickup?

A: Misfiring, poor starts, RPM instability, or no spark at all.

Q5: Can I upgrade the CDI system on the Thor 250?

A: Yes, but ensure compatibility with the stock pickup and always test before flight.

Also read : Everything You Need to Know About the Mobility Scooter Jazz Model Name / Number: 20k Elite